As a power transmission system in electric drive, the reducer can reduce speed and increase torque to meet the normal power demand of users. It mainly includes gear system, bearing, differential, housing and other accessories. The key attributes and performance requirements are space size, weight, efficiency and NVH.

Current electric drive reducers predominantly feature a single-speed, two-stage parallel shaft design, which offers a simple structure and high cost-effectiveness, making it the undisputed mainstream solution. However, as users increasingly demand more space and range in vehicles, the pressure on various subsystems grows significantly. As a critical component, electric drive reducers now face substantial challenges in space, weight, and efficiency. Leading OEMs and international powertrain giants are actively exploring innovative architectures, such as planetary gear arrangements.

Currently, planetary gear mass-production models are predominantly found in mid-to-high-end vehicles from international brands like Audi e-tron, Jaguar Land Rover I-Pace, and Lucid Air. In China, only the Jike brand and select Geely models will adopt this technology starting in 2024. Meanwhile, the passenger car planetary gear supply chain market is almost entirely dominated by global giants such as Schaeffler and ZF. Domestic manufacturers like Xingqu are actively expanding their presence in this field. Moving forward, coaxial planetary gears are expected to gain significant market traction, particularly in mid-to-high-end vehicle segments.

The requirement for high compactness in transmission systems

▶ present situation

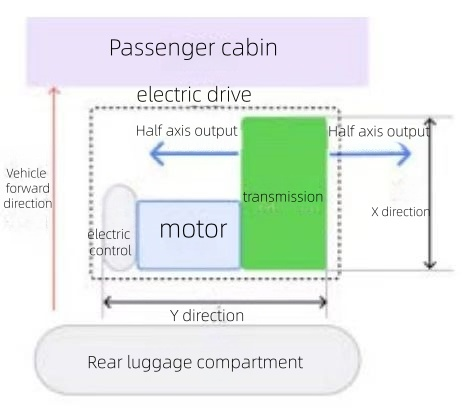

As a key powertrain component, the electric drive greatly affects the vehicle layout. With the increasing demand of the public for the interior space and luggage compartment space, and the platformization of the vehicle and powertrain, the powertrain is required to have a high adaptability to the vehicle layout.

Therefore, the space and regularity of the electric drive are required to be higher. As shown in the figure below, the size of the transmission system directly affects the X direction (longitudinal direction of the vehicle) of the electric drive, and then affects the space in the car or the space in the luggage compartment.

Figure 1 Schematic diagram of transmission system layout Source: Public information

The current transmission system predominantly employs parallel shaft configurations, where the X-axis dimensions are directly influenced by the distance between the input and output shafts. Industry standards for X-axis dimensions are generally as outlined in the table below. Although planetary gearboxes currently hold a small market share, their demand is projected to grow significantly in the future. Schaeffler, a leading advocate of planetary gearboxes, has developed models with X-axis dimensions 30% to 40% smaller than traditional parallel shaft systems.

torque output

<3000Nm

3000-4000Nm

4000-5000Nm

X-axis dimension

<400mm

400-600mm

460-480mm

▶ throw down the gauntlet

The current transmission system compresses the space to the extreme. After reducing the center distance, it faces risks of shaft-to-tooth strength and NVH (Noise, Vibration, and Harshness).

The reduced center distance imposes constraints on macroscopic parameters of the gear teeth, including module limitations, root bending risks, and tooth surface contact strength challenges. Furthermore, the heightened torque response and frequent regenerative braking demands in new energy vehicles impose stricter strength requirements on gear teeth and differentials. Optimization is required in material selection, heat treatment processes, and surface strengthening techniques.

The need for lightweight transmission systems

▶ present situation

For new energy vehicles, particularly pure electric models, range is a key concern for users, while weight significantly impacts driving range. The electric drive accounts for approximately 5% of the total vehicle weight, with the transmission system making up about 50% of the electric drive’s weight. Since the transmission system’s weight directly affects both cost and dimensions, low weight is also a critical requirement for the electric drive.

Currently, parallel shaft reducers dominate the market with over 95% adoption, where weight correlates with output torque as shown in the table below. The Zhi Ji L7/L6 series features magnesium-aluminum alloy housings, achieving 30% lighter weight than conventional aluminum alloy housings. Although planetary gearboxes currently hold a small market share, their demand is projected to grow significantly. As a pioneer in planetary gear reducer technology, Schaeffler’s solutions reduce weight by 30% to 40% compared to traditional parallel shaft reducers.

torque output

<3000Nm

3000-4000Nm

4000-5000Nm

Weight (dry weight)

<25kg

25-30kg

30-35kg

▶ throw down the gauntlet

To meet the demand for lightweight transmission systems, reducers are typically optimized through structural design and material selection. Structural optimization directly reduces material usage, but this approach also introduces risks of strength and reliability, as well as NVH (Noise, Vibration, and Harshness) issues. While magnesium-aluminum alloy housings are cost-effective, they suffer from high-temperature creep and poor stiffness, which further exacerbates NVH risks.

The need for efficient transmission

▶ present situation

Another critical factor affecting vehicle range is electric drive efficiency. Beyond CLTC (China’s New Energy Vehicle Testing and Certification) standards, high-speed constant-speed efficiency has become a key concern for users. Common high-speed driving conditions like 100 km/h and 120 km/h require high-efficiency high-speed transmission systems with low torque output. Key considerations include transmission architecture, shaft layout, bearing selection, gear precision, housing cavity design, and lubricant choice.

With OEMs adopting assembly applications, refined operational conditions, and advancements in component technologies, the CLTC efficiency of gearboxes has been steadily improving. Before 2020, the CLTC efficiency was generally around 97%, with some manufacturers achieving 97.5%. For instance, XPeng Motors’ G9 (2022 model) demonstrated a measured CLTC efficiency exceeding 97.5%, while the G6 (2023 model) reached 97.6%.

▶ throw down the gauntlet

At present, the high efficiency reducer is basically through reducing the torque loss and reducing the speed loss.

Reduce torque loss by improving gear meshing precision, reducing tooth surface roughness and slip rate, and using low rolling resistance ball bearings.

Reducing speed loss: The dry oil pan minimizes oil agitation loss, and low-viscosity lubricants are recommended.

The high meshing precision and low tooth surface roughness will put forward higher requirements for the shaft gear machining technology and production rhythm, and also mean higher production cost. The protection ability of the shaft gear bearing will be reduced when low viscosity lubricating oil is selected, which brings higher challenge to the reliability of the shaft gear bearing.

The need for low-noise transmission

▶ present situation

As consumers increasingly prioritize vehicle quietness, the lack of engine noise masking in electric drive systems makes their noise more noticeable. Moreover, the noise from electric drive gearboxes typically falls within the mid-to-high frequency range that users can easily perceive. With recent advancements in domestic vehicle manufacturing processes and material quality, the overall sound quality of vehicles has significantly improved, which has further accentuated the whistling noise from electric drive systems.

In modern drivetrain systems, NVH issues have expanded beyond shaft-to-tooth squealing. Customers now prioritize ride comfort and acoustic quality, while also noticing clunking noises and jerky transitions during torque shifts. This reflects the growing complexity of NVH challenges in automotive engineering.

In standard transmission systems, the semi-damp chamber typically produces an average noise level of 5 decibels (dB) at 1 meter distance and around 70dB(A) under full torque conditions, with some manufacturers achieving noise levels below 65dB(A).

▶ throw down the gauntlet

Compared to conventional vehicles, new energy vehicles face greater NVH (Noise, Vibration, and Harshness) development challenges due to the absence of the masking effect from internal combustion engines and users’ growing demand for cabin quietness. The transmission system noise in these vehicles predominantly involves mid-to-high frequency sounds that are particularly sensitive to human ears. With numerous rotating components and significant challenges in mass production and assembly stability, transmission noise has become a major source of customer complaints.

NVH (Noise, Vibration, and Harshness) is a subjective perception closely tied to cost considerations. As user expectations vary across different vehicle segments, establishing NVH development objectives must first align with the vehicle’s positioning and target user demographics. The resolution of NVH issues spans the entire vehicle development lifecycle. Once identified, the process involves testing, analysis, computational simulations, problem categorization, solution formulation, and validation. Beyond a robust development process, hands-on experience plays a pivotal role in addressing these challenges.

To address transmission system squealing, structural excitation is the root cause, while path control is equally critical. NVH improvement strategies targeting both source and path often conflict with lightweighting requirements while driving up costs. Beyond the inherent complexity and evolving demands of NVH challenges, achieving multidimensional balance between NVH mitigation measures, lightweighting, and cost control poses a significant decision-making challenge for OEMs and suppliers at all levels.